Industry News

Skorpion Engineering uses 3D printing technology to quickly produce lightweight automotive parts

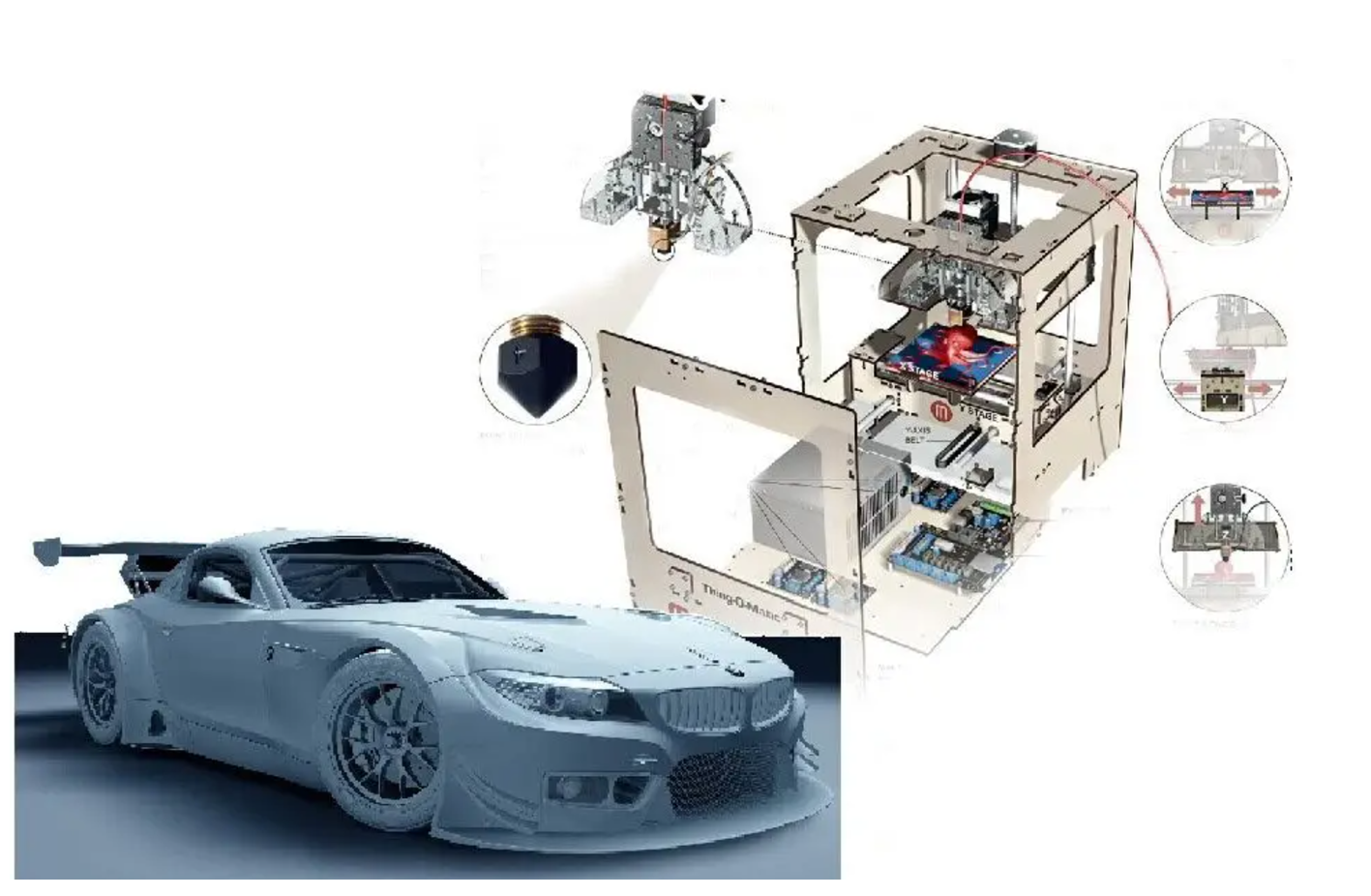

According to foreign media reports, many auto manufacturers have started to use 3D printing technology. BMW, Rolls Royce, Ford and other companies have all adopted 3D printing technology. Companies like Local Motors have started to innovate because some companies first proposed full 3D printing car bodies.

Today, Skorpion Engineering uses six Stratasys 3D printers in its headquarters in Milan and Turin to improve the production efficiency of its prototype vehicles by 50% compared with the previous method. At present, they are producing samples of various parts, including seat frames and even door handles. With the PolyJet 3D printer, on-demand production can be achieved and the prototype is ready within 24 hours.

The company's new technology has increased business, because customers are satisfied with the improved prototype and the completion period is shorter. For example, for a project, the Skorpion team built a full-size bumper for the car. With the Fortus 900mc production 3D printer, they can process parts faster. Customers also appreciate one of the other advantages of 3D printing prototypes: the parts are very light, especially compared with clay.

They can also use the Objet350 Connex3 3D printer to realize the rapid printing and production of on-board dashboard. With its advanced features, the team can also create different textures at the same time.

Moriggi explained: "As we continue to promote the prototype design capability of 3D printers, we are finding that they have wider manufacturing potential. In fact, they aim to use additive manufacturing to achieve the production of full-featured concept cars in the next five years."

Origin: Gesco